Polyphytes

4D Printing | Procedural 3D modelling

Vascular 3D printed plant forms created with new PolyJet feature that enables printing with liquid

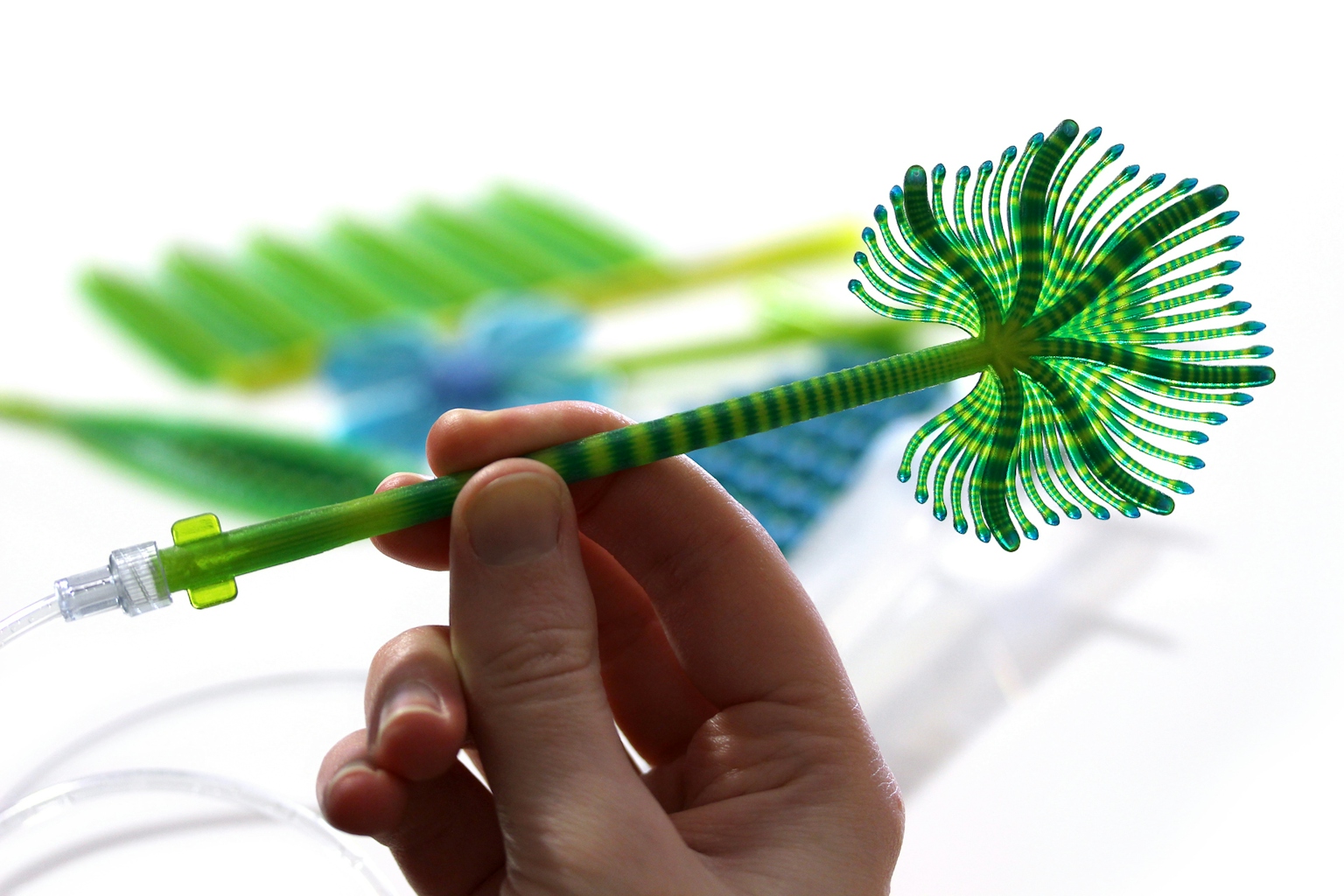

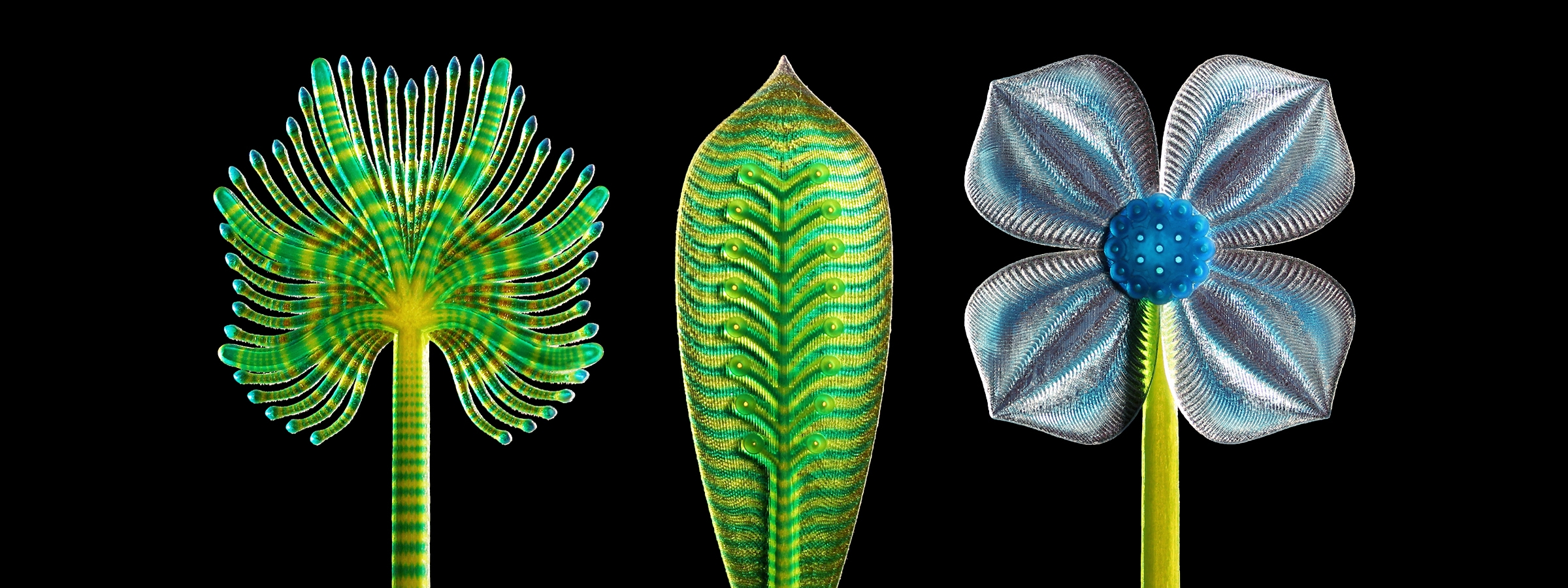

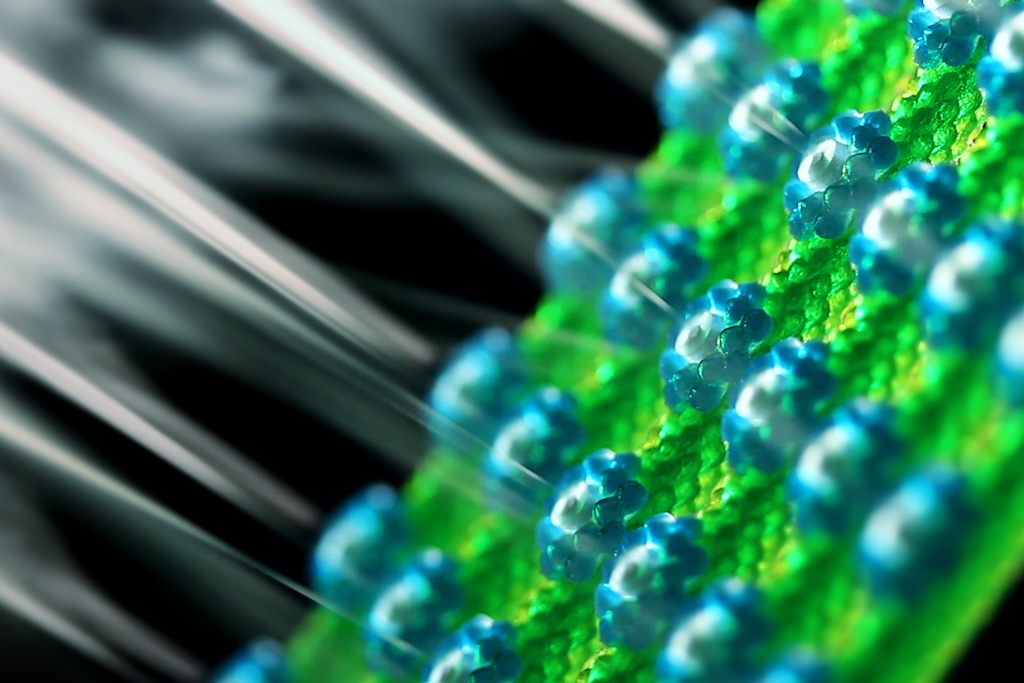

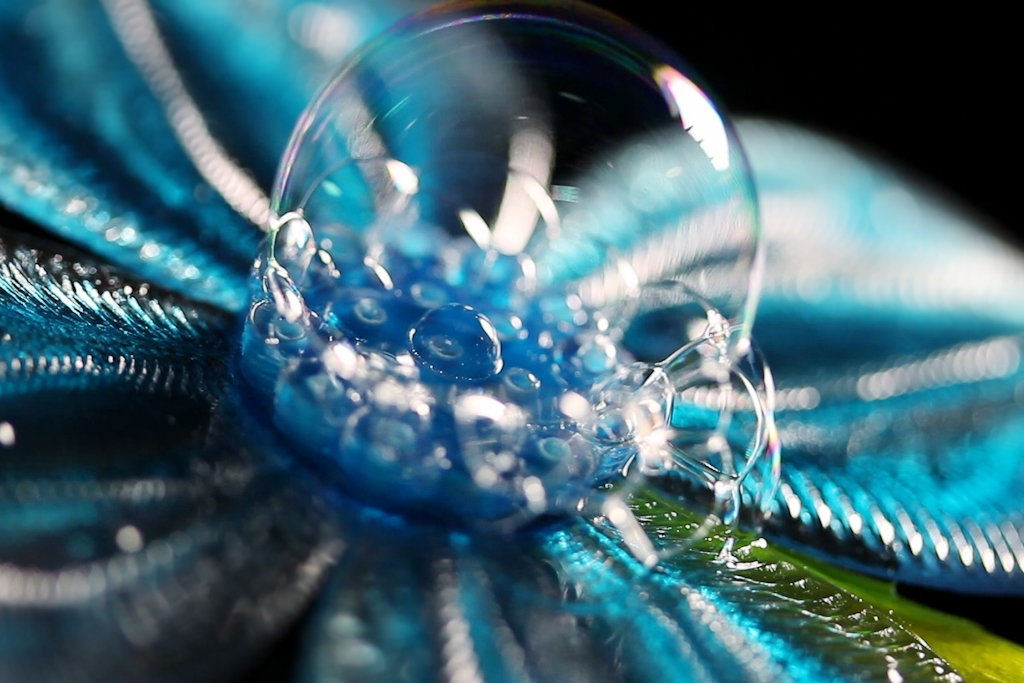

The Polyphtes utilise Liquid Print to create fluidic models that perform like vascular systems in plants. The project demonstrates the dynamic qualities of 4D printing by creating 3D prints that can function and change their aesthetic as various mediums flow through their internal channels; water, air, smoke, icing sugar, bubble mixture and soap. The physical effects seen in the film evoke the beauty of natural pollination and the transportation of nutrients in plant life.

Design Tools

Houdini, Stratasys J850 3D Printer + Liquid Print, Premiere Pro

attribution

Project completed through MADE group from Victoria University of Wellington, directed by Ross Stevens. Access to new software through Stratasys Research Package.

Features

Precursor Project

Printing with liquid

The Polyphytes explore a new feature of PolyJet technology - Liquid Print. This allows the creation of airtight cavities filled with liquid inside an object. Previously, such cavities would have been filled with support material and difficult to clean out.

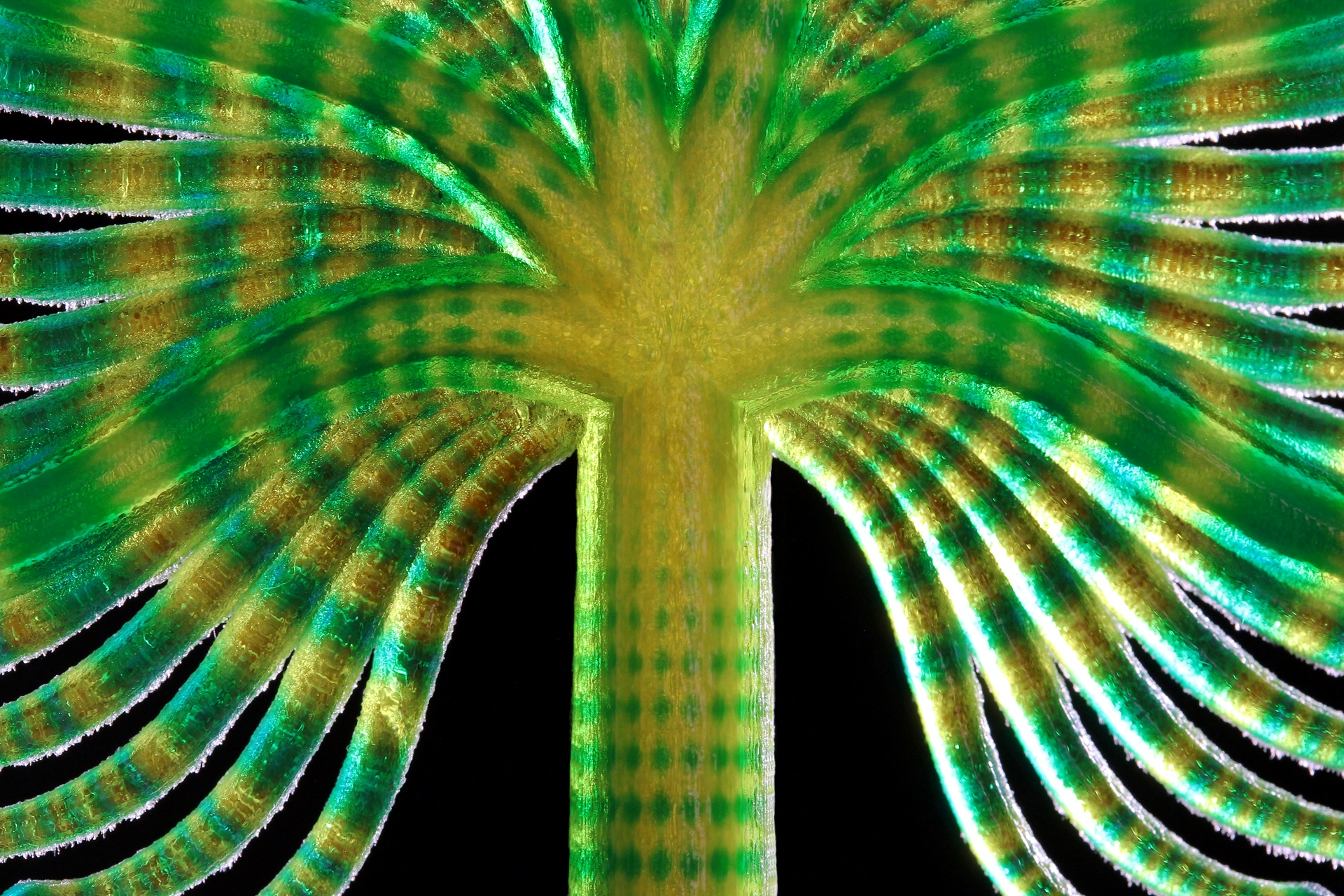

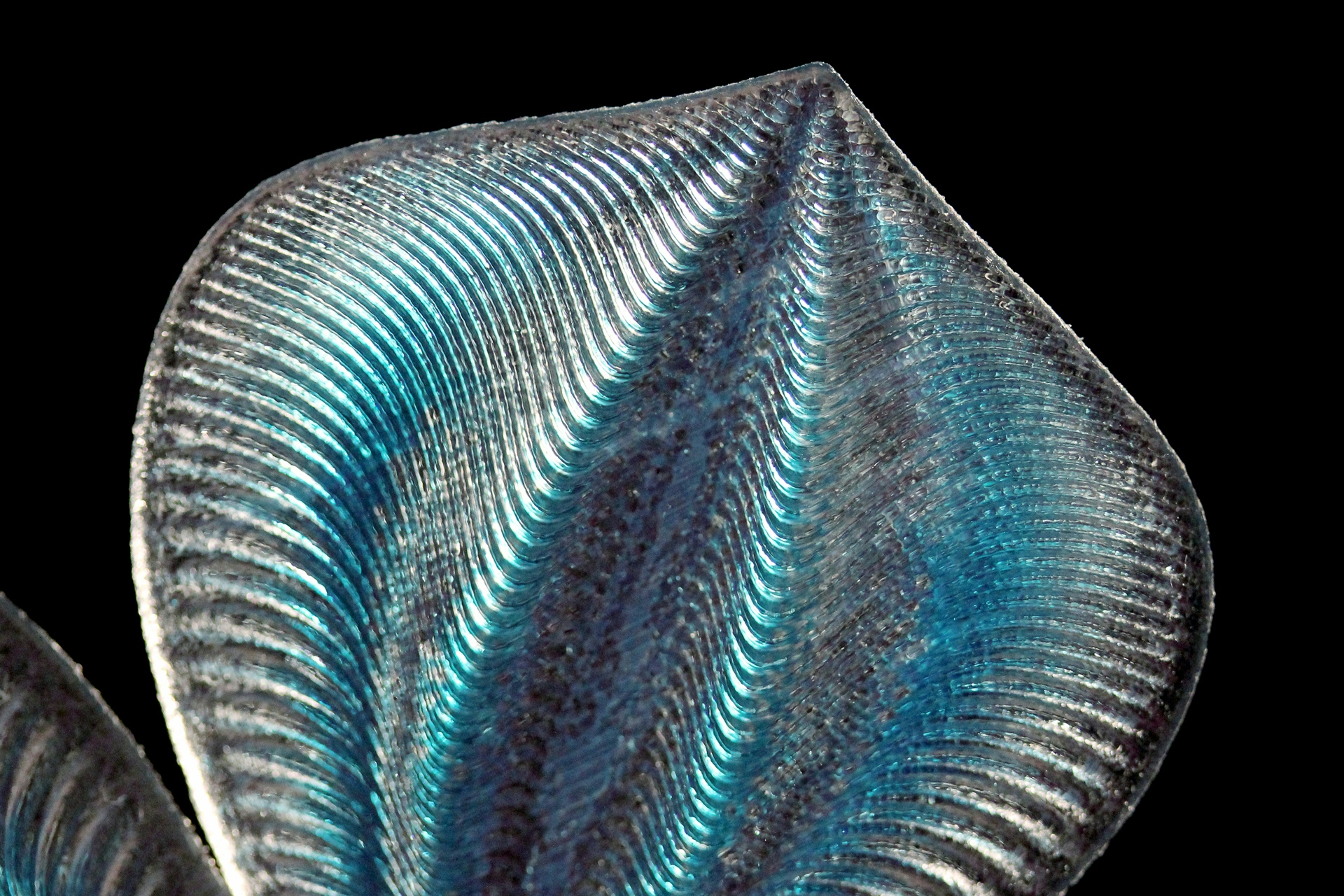

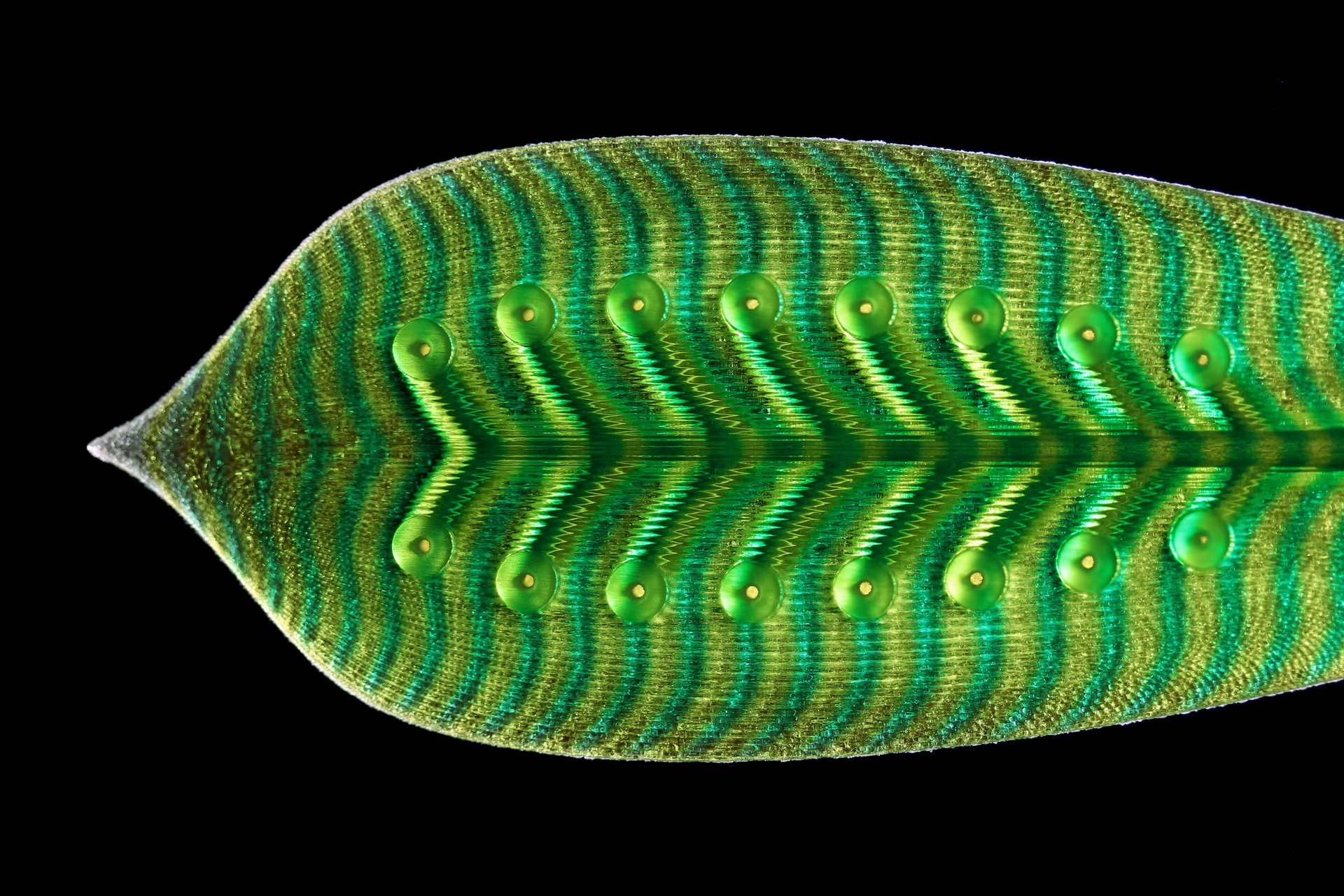

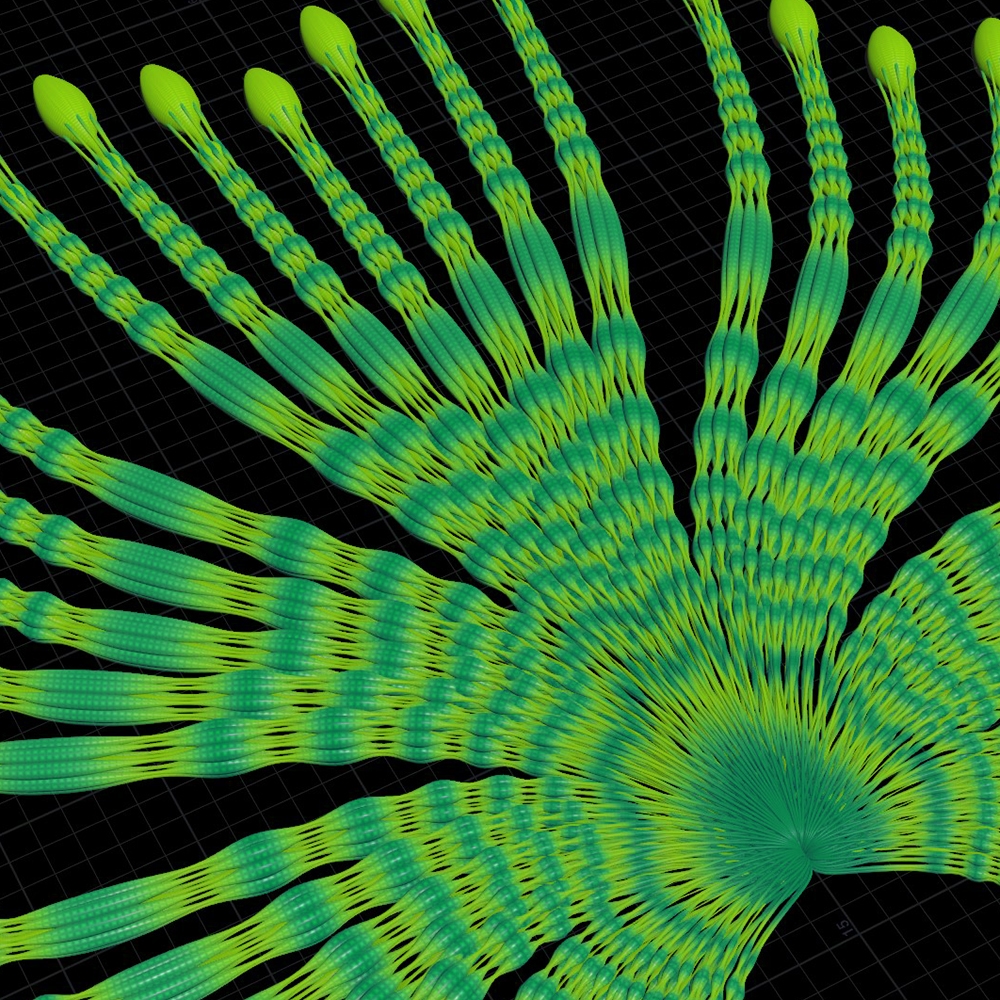

The Polyphytes are created in Houdini with a series of internal channels, some as small as 1mm in diameter. Parts of their procedurally generated patterning can be seen in the images above. The models are printed on the Stratasys J850 in full-colour rigid photopolymer resin with variable levels of opacity. The enclosed voids are initially filled with PolyJet cleanser (liquid) which is drained out in post-production. This allows the channels to become instantly free-flowing.